Latest topics

Photo of the Murray Curvex Machine in operation!

Page 1 of 1

Photo of the Murray Curvex Machine in operation!

Photo of the Murray Curvex Machine in operation!

Many thanks to MonG for sharing these photos from a New Zealand magazine from 1977 and to Tom Clark Jnr for explaining what is happening

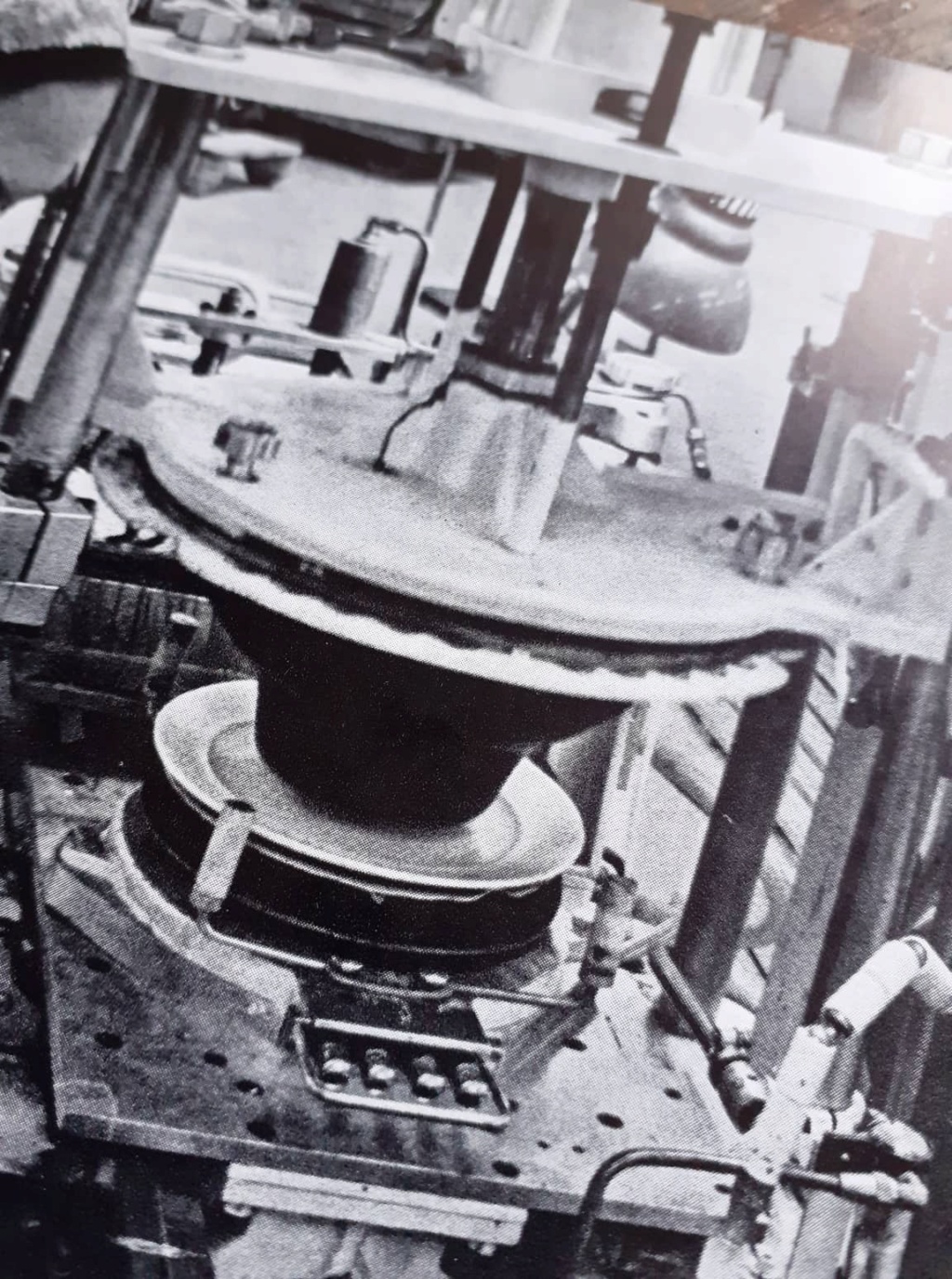

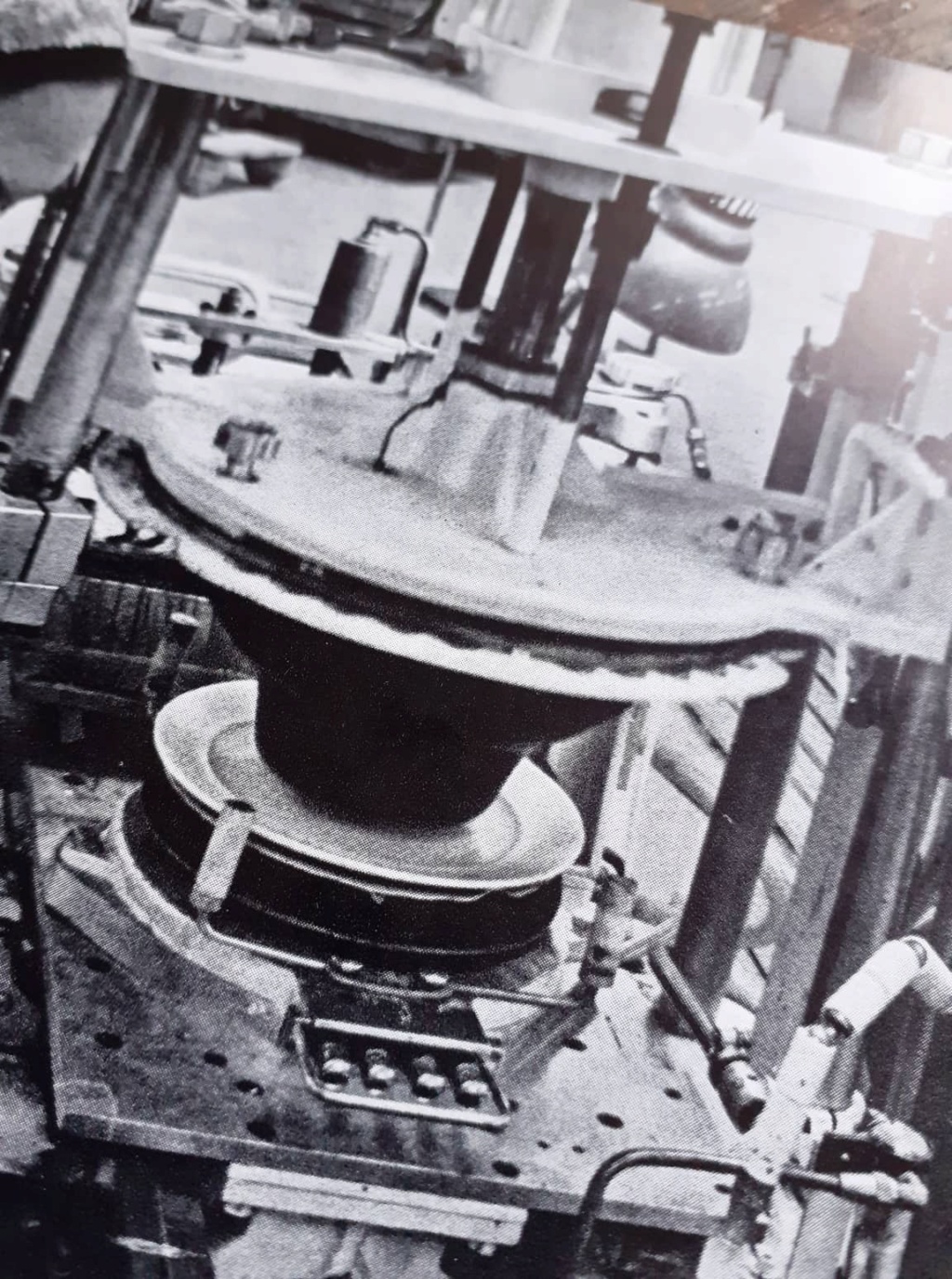

Tom Clark kindly responded to this photo and has enlightened me regarding the Murray Curvex Machine that is being used in the photo. "This photo shows the printing of the pattern on to the earthenware plate using the Murray Curvex offset printing machine.

The pattern was photo etched on to a copper plate which was then chrome plated. Ceramic ink was swept across the plate and the gelatine ' bomb' as pictured came down and pressed on to the plate and picked up the image

using a sliding carriage a earthenware bisque plate was slid into position

The bomb came down and the image was transferred from the bomb to the eathenware plate. This machine decorated about 2000 pieces per day

There were 6 machines

The original was purchased from Ceramic Engineers England

The other 5 were built by Crown Lynn engineers

Hundreds of patterns were produced by this method

Finally 2 Decram machines were purchased which enabled 3 colors to be produced from the one machine

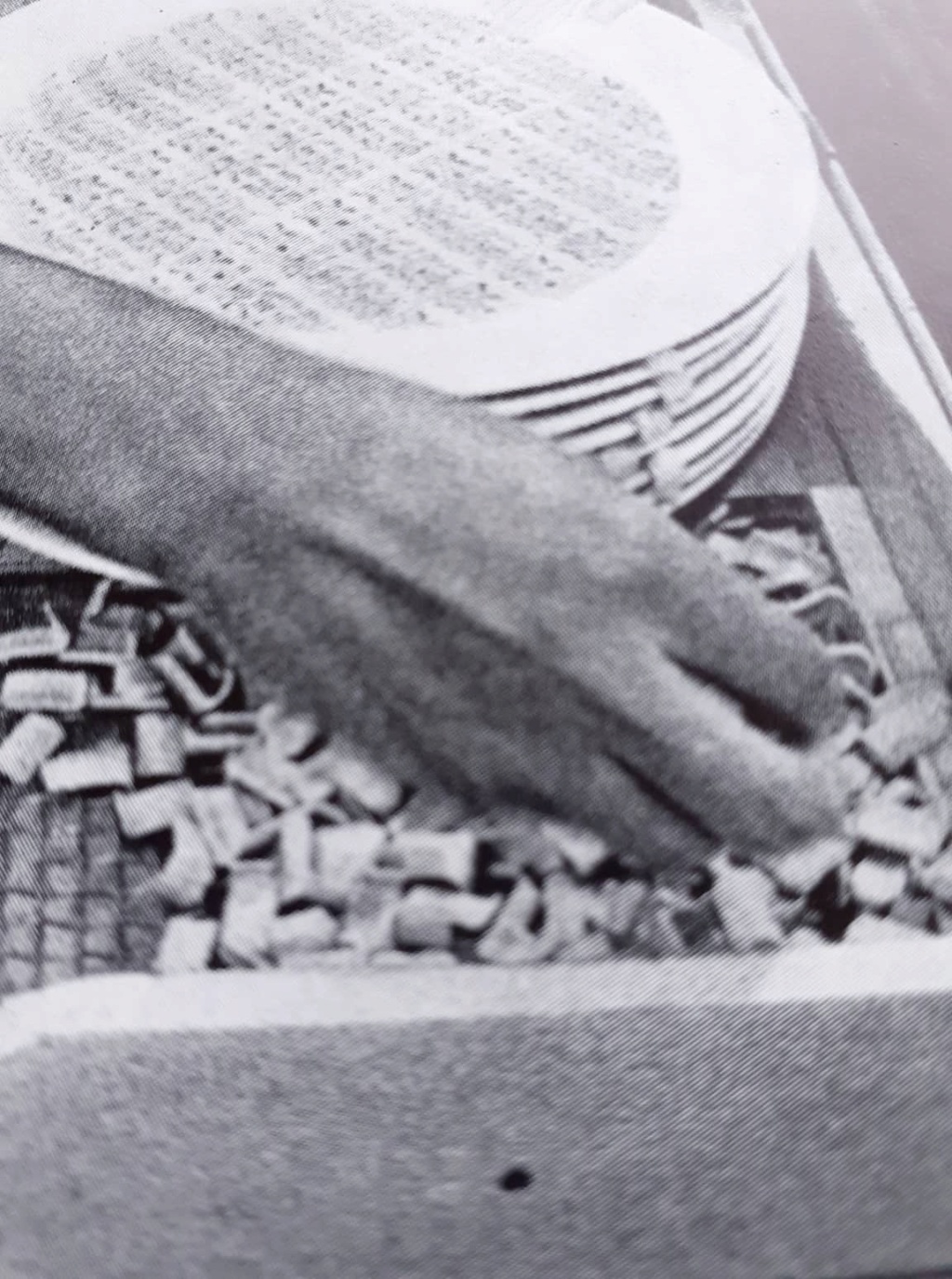

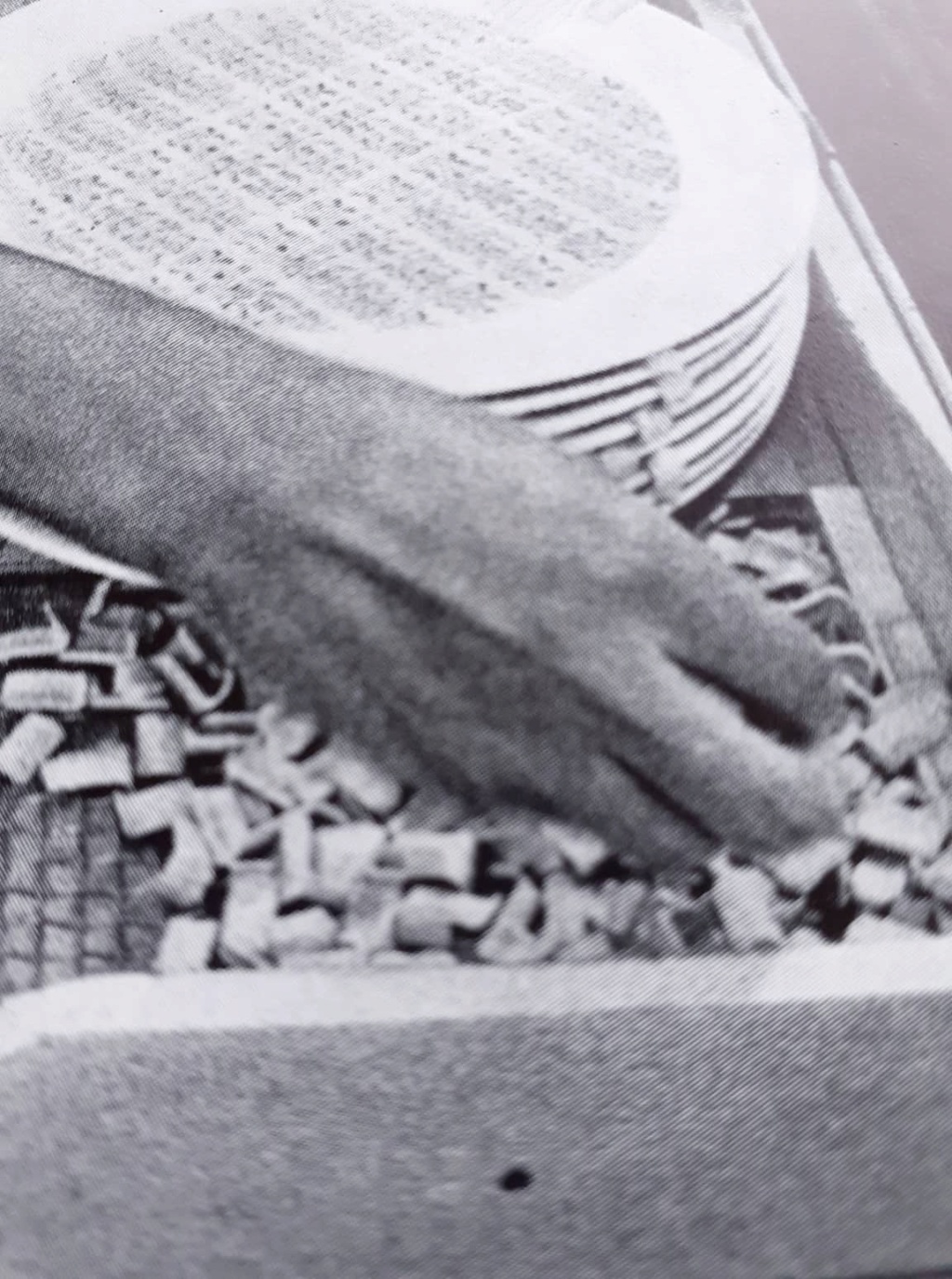

After printing the plates were stacked up separated by pins. Pictured. Then glazed.

Tom Clark continues "After glazing the plates were placed in in ceramic cranks and each plate was supported by 3 firing pins

These left the characteristic

3 marks on the back of the plates

Plate setters were used in the firing of the stoneware patterns only

The ware was glazed at green. Foot wiped then placed on setters these patterns all were designed with a foot and different from normal production

The stoneware was fired on the min kiln

So you see quite a few different firing conditions were employed at Crown Lynn"

Tom Clark kindly responded to this photo and has enlightened me regarding the Murray Curvex Machine that is being used in the photo. "This photo shows the printing of the pattern on to the earthenware plate using the Murray Curvex offset printing machine.

The pattern was photo etched on to a copper plate which was then chrome plated. Ceramic ink was swept across the plate and the gelatine ' bomb' as pictured came down and pressed on to the plate and picked up the image

using a sliding carriage a earthenware bisque plate was slid into position

The bomb came down and the image was transferred from the bomb to the eathenware plate. This machine decorated about 2000 pieces per day

There were 6 machines

The original was purchased from Ceramic Engineers England

The other 5 were built by Crown Lynn engineers

Hundreds of patterns were produced by this method

Finally 2 Decram machines were purchased which enabled 3 colors to be produced from the one machine

After printing the plates were stacked up separated by pins. Pictured. Then glazed.

Tom Clark continues "After glazing the plates were placed in in ceramic cranks and each plate was supported by 3 firing pins

These left the characteristic

3 marks on the back of the plates

Plate setters were used in the firing of the stoneware patterns only

The ware was glazed at green. Foot wiped then placed on setters these patterns all were designed with a foot and different from normal production

The stoneware was fired on the min kiln

So you see quite a few different firing conditions were employed at Crown Lynn"

Maryr, JanPots and Truffles like this post

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum

» Glenn Beattie

» NOT a Sherwood Pottery Galleon, as Made in Japan

» Minna Bondy

» Jan Gillespie

» Studio Ceramics wall swan...

» Hamilton Boys High and Old Folks Assoc. Hamilton Badgeware

» Studio Ceramics Villagio and Porto

» Studio Ceramics swans and dimensions